Electrical Safety Inspections for Businesses: Why They Matter

Keeping You Compliant and Protected

One overlooked wiring issue can bring your operations to a standstill and put your team in harm's way in an instant. Businesses across Renfrew County and Woodstock are held to strict standards by the National Electric Code (NEC) and the Ontario Electrical Safety Code to ensure the safety of everyone and everything on your premises. Commercial electrical safety inspections provide a detailed review of your electrical panels, wiring, grounding, and equipment to pinpoint potential risks, confirm you're meeting all requirements, and boost your energy efficiency. This guide will walk you through:

How inspections help you avoid costly downtime, legal headaches, and wasted energy

What a complete inspection entails, from checking every component to verifying code adherence

Recommended inspection frequencies based on NFPA 70B and NFPA 70E guidelines

Key requirements from the NEC and Ontario codes, and what happens if you don't comply

Strategies to identify and reduce risks like arc flash, electric shock, and fires

Specialized services such as panel upgrades, arc flash assessments, and ongoing maintenance

Why B-Line Electric's local knowledge, certifications, and customized approach are the right choice for you

By understanding each of these points, you'll see how being proactive with inspections is a smart investment in both your business's financial health and the well-being of your people.

Why Are Commercial Electrical Safety Inspections Absolutely Essential for Your Business?

Commercial electrical safety inspections are more than just a check-up; they're a comprehensive process of assessing risks, confirming code compliance, and testing performance to minimize hazards, reduce legal exposure, and prevent operational disruptions. By thoroughly examining your entire electrical system, our inspectors help ensure your business runs without interruption, keeps employees and customers safe, and meets all the necessary NEC and provincial standards.

How Do Electrical Inspections Prevent Costly Downtime and Disruptions?

Regular inspections are key to keeping your electrical system running reliably by catching problems before they force a shutdown. When we identify issues like overloads, corrosion, or loose connections early on, we can prevent unexpected outages and keep your business operations running smoothly.

Before you set up a maintenance plan, it's helpful to see how common electrical failures can impact your business:

This breakdown clearly shows how consistent checks turn potential disruptions into manageable maintenance tasks, setting the stage for effective hazard identification.

What Are the Risks of Ignoring Workplace Electrical Safety?

When businesses neglect electrical safety, the consequences can be severe – financially, legally, and in terms of human impact. Faulty wiring can spark fires that destroy valuable inventory and property, arc flash incidents can lead to life-altering injuries, and failing to comply with regulations can result in escalating fines, damage to your reputation, and serious sanctions. A proactive inspection program helps uncover hidden faults, significantly lowering the chance of catastrophic failures and costly insurance claims. Understanding these risks truly highlights the importance of scheduled electrical evaluations.

Electrical Safety in the Workplace - Why It's Non-Negotiable

This article emphasizes the critical importance of electrical safety in commercial environments, stressing the necessity of regular inspections to prevent hazards and ensure adherence to safety codes. It details the potential financial, legal, and human costs associated with neglecting electrical safety, underscoring the vital need to comply with the National Electrical Code (NEC) and all local regulations.National Fire Protection Association (NFPA), Electrical Safety in the Workplace (2024)

This information strongly supports our focus on electrical safety and the necessity of following the NEC.

How Do Inspections Ensure the Safety of Your Employees and Customers?

Inspections confirm that your circuit protection, ground fault interrupters, and emergency shut-off systems are working correctly, directly reducing the risk of electric shock or arc flash injuries. By testing protective relays, verifying insulation quality, and ensuring proper personal protective equipment (PPE) is in place, our inspectors elevate your workplace safety standards and foster a culture of compliance and care. Maintaining safe electrical conditions builds trust with your staff and clients, ensuring smooth operations and reinforcing your brand's reliability.

Why Is Staying Compliant with the NEC and Ontario Electrical Safety Code So Important?

The NEC and the Ontario Electrical Safety Code provide the essential legal guidelines for the safe design, installation, and upkeep of electrical systems in commercial settings. By following these standards, your business can avoid penalties, maintain your building insurance coverage, and demonstrate that you're actively managing risks. Being clearly compliant also makes official inspections smoother and simplifies any future upgrades or expansions. Recognizing these requirements shows that safety inspections are a crucial investment in both legal protection and responsible business practice.

Ontario Electrical Safety Code: Your Guide to Safe Electrical Systems

The Ontario Electrical Safety Code (OESC) lays out the rules for safely designing, installing, and maintaining electrical systems throughout Ontario. It's based on the Canadian Electrical Code and is overseen by the Electrical Safety Authority (ESA).Electrical Safety Authority (ESA), Ontario Electrical Safety Code (2024)

How Can Electrical Inspections Lead to Better Energy Efficiency and Lower Costs?

Inspections can uncover issues like overloaded circuits, unbalanced loads, and worn-out components that unnecessarily increase energy use and put extra strain on your equipment. Once these inefficiencies are identified, we can recommend targeted repairs or upgrades—such as swapping out old motors or tightening connections—to help lower your electricity bills and extend the life of your equipment. Over time, these energy savings add up, providing a strong return on your investment in routine safety inspections and supporting your company's sustainability goals.

What Does a Comprehensive Commercial Electrical Safety Inspection Involve?

A complete inspection includes a thorough review, hands-on system assessment, code verification, hazard analysis, and a detailed report with practical recommendations. This all-encompassing approach ensures your system is as reliable as possible and meets all regulatory requirements.

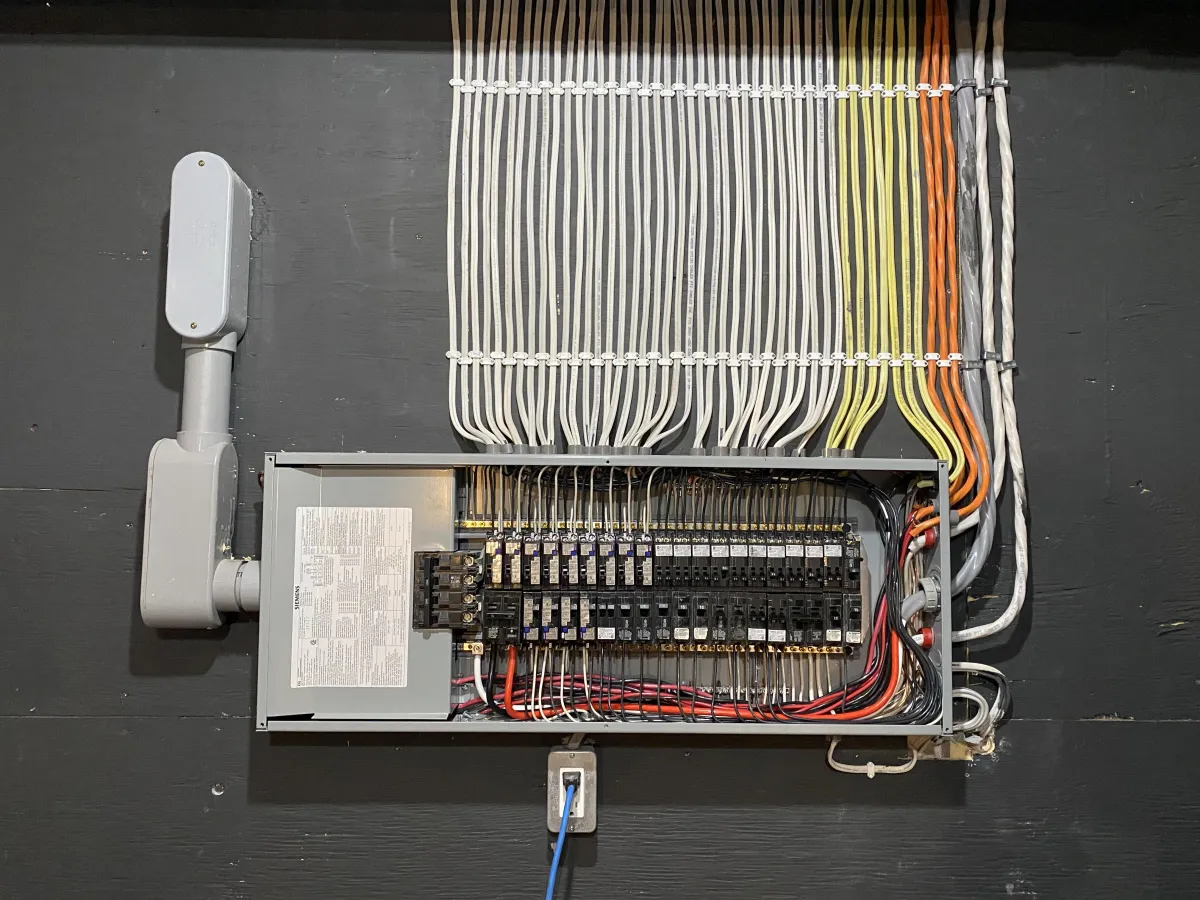

Which Electrical System Components Are Checked During Inspections?

Our inspectors examine all critical components to ensure they're operating safely and efficiently. This includes main and sub-panels, branch circuit wiring, grounding systems, motor control centers, and emergency power equipment.

Here’s a typical checklist of what we evaluate:

This detailed checklist ensures every part of your electrical infrastructure is assessed, providing a solid foundation for code compliance and risk reduction.

How Do We Verify Code Compliance with NEC and Local Standards?

We verify compliance by comparing your equipment ratings, conductor sizes, overcurrent protection, and wiring methods against specific NEC articles and Ontario Electrical Safety Code rules. Our inspectors review permit documentation, measure voltage drops, confirm conductor ampacities, and check clearances around live electrical parts. Documenting every test and referencing the relevant code sections creates a clear audit trail that simplifies reviews by authorities and supports safe operations.

What Are Common Electrical Hazards Found in Commercial Settings?

Commercial environments often present hazards such as arc flash, equipment overloads, exposed live wiring, and compromised grounding. Our inspectors focus on identifying:

Factors contributing to arc flash, like high fault currents and insufficient PPE

Ground fault paths that could lead to dangerous voltage levels

Exposed conductors in areas prone to moisture or corrosion

Older circuit breakers that may have delayed trip responses

Pinpointing these hazards allows us to create targeted solutions that strengthen your safety measures and prevent potential losses.

What Information Is Typically Included in the Inspection Report and Recommendations?

A standard inspection report provides an executive summary, details on system evaluation findings, identified hazards, any code violations, prioritized recommendations, and estimated costs. By clearly categorizing urgent repairs versus longer-term upgrades, we help you make informed decisions about resource allocation. With photos, test data, and references to specific code sections, the report serves as a clear roadmap for improving both safety and performance.

How Often Should Businesses Schedule Electrical Safety Inspections?

Businesses benefit most from routine inspections scheduled based on how critical your equipment is, industry best practices, and your specific risk profile. Maintaining the right inspection intervals keeps your system in top condition and ensures you remain compliant with regulations.

What Do NFPA 70B and NFPA 70E Say About Inspection Intervals?

NFPA 70B suggests preventive maintenance inspections at least annually for most industrial electrical equipment. NFPA 70E requires risk assessments and maintenance schedules tailored to how equipment is used and safety analyses. For systems that are used continuously or are critical to operations, more frequent checks—either semi-annually or quarterly—may be necessary to manage higher hazard risks.

When Are More Frequent Inspections Necessary?

Systems that operate constantly, handle heavy mechanical loads, or have a history of safety incidents require more frequent inspections. If maintenance has been missed or if an inspection reveals existing issues, follow-up checks might be needed every 3–6 months until full compliance and reliability are achieved.

How Does Regular Maintenance Help Prevent Electrical Failures?

Regular maintenance inspections involve replacing worn parts, tightening connections, cleaning contacts, and testing protective devices. This proactive approach minimizes unexpected breakdowns and ensures your system is available when you need it, highlighting the value of ongoing safety partnerships.

What Are the Key Commercial Electrical Code Compliance Requirements?

Commercial code compliance covers essential aspects like conductor sizing, overcurrent protection, equipment grounding, safe working clearances, and proper wiring methods. Meeting these requirements is fundamental to safe design, installation, and ongoing operations.

What Are the National Electric Code (NEC) Standards for Businesses?

The NEC provides guidelines for wiring methods, conductor capacities, panelboard installations, disconnect requirements, and emergency power systems in commercial buildings. Following NEC articles ensures that protective devices work together correctly, loads are balanced, and fault current ratings are adequate.

How Does the Ontario Electrical Safety Code Impact Local Businesses?

The Ontario Electrical Safety Code builds upon NEC guidelines with specific provincial rules covering inspection schedules, required qualifications for electricians, and reporting procedures. Local businesses must adhere to the permit and inspection processes mandated by the ESA for any renovations, new installations, or significant equipment changes.

What Are the Penalties for Not Complying with Electrical Codes?

Failing to comply with electrical codes can lead to fines, loss of permits, higher insurance costs, and liability for damages. Serious violations might result in orders to stop work, legal action, or even personal liability for company executives. Staying proactive with compliance inspections significantly reduces these financial and operational risks.

How Does NFPA 70E Compliance Enhance Workplace Electrical Safety?

NFPA 70E is focused on protecting workers through hazard analysis, specifying PPE, establishing safe work procedures, and providing training. By implementing NFPA 70E protocols, businesses can reduce arc flash exposure, minimize shock hazards, and ensure clear lockout/tagout practices are followed, further safeguarding both people and property.

How Can Businesses Identify and Prevent Workplace Electrical Hazards?

Effective hazard prevention involves recognizing potential dangers, implementing engineering controls, and establishing administrative procedures to eliminate or minimize electrical risks in the workplace.

What Are Arc Flash Hazards and How Can They Be Managed?

Arc flash hazards occur when a high-energy electrical discharge rapidly vaporizes metal, creating a powerful blast. Strategies to manage these risks include:

Arc flash studies to determine the potential incident energy levels

Selecting the correct PPE based on calculated energy exposures

Using protective devices designed for fast-acting trip responses

Implementing these controls helps limit potential injuries and damage to your facility.

How Can Electrical Shock Risks Be Reduced in Commercial Buildings?

Preventing electrical shock involves ensuring proper grounding, installing ground fault circuit interrupters (GFCIs) in damp areas, using insulated tools, and training staff on safe work practices. Verifying the continuity of bonding and maintaining protective barriers around live electrical components further reduce the risk of shock.

What Fire Safety Measures Are Crucial for Electrical Systems?

Essential fire prevention measures include:

Thermal imaging scans to detect overheating components

Surge protection devices to manage sudden voltage spikes

Regular cleaning of panel interiors to remove dust and debris

Maintaining proper clearances around equipment to prevent ignition sources

These steps are vital for reducing fire risks and protecting your assets.

How Do Lockout/Tagout Procedures Improve Electrical Safety?

Lockout/tagout procedures ensure equipment is safely disconnected from power sources, preventing accidental re-energization during maintenance. Clearly marking isolation points, using secure locks, and providing thorough employee training guarantee safe working conditions and minimize the risk of unintended energization.

What Specialized Commercial Electrical Services Complement Safety Inspections?

Specialized services enhance safety inspections by providing advanced analysis, system upgrades, and ongoing maintenance to ensure continued compliance and optimal performance.

How Do Electrical Panel Inspections and Upgrades Boost Safety?

Inspecting electrical panels helps identify loose connections, corrosion, and outdated components that can compromise protective coordination. Upgrading to modern circuit breakers with arc flash reduction features and adding surge arresters strengthens your system's resilience and lowers the chance of fault-related failures.

These targeted upgrades transform older electrical infrastructure into safer, more efficient systems.

Why Are Wiring and System Integrity Checks So Important?

A thorough wiring inspection confirms proper conductor routing, secure connections, and adequate strain relief. Identifying damaged insulation or undersized conductors is crucial for preventing overheating, arc faults, and potential fire hazards, ensuring long-term electrical reliability.

What Is Arc Flash Analysis and How Does It Reduce Risk?

An arc flash analysis calculates the potential incident energy and arc flash boundaries, guiding the selection of appropriate PPE and protective devices. By quantifying these hazards, businesses can implement engineering controls and administrative procedures that directly lower the risk to personnel and equipment.

How Do Preventative Maintenance Programs Benefit Businesses?

Preventative maintenance programs involve regular inspections, testing, and minor repairs to keep your electrical system in optimal condition. By addressing wear and tear before it leads to failures, these programs improve uptime, extend equipment lifespan, and provide predictable maintenance costs—ultimately boosting your overall operational efficiency.

Why Partner with B-Line Electric for Your Business Electrical Safety Needs?

B-Line Electric offers local expertise, certified professionals, and a dedicated customer-focused approach to commercial electrical safety inspections. As a family-owned business, we prioritize personalized service and proactive solutions to your electrical challenges.

How Does Our Local Expertise in Renfrew County and Woodstock Benefit Your Business?

Our in-depth knowledge of regional climate conditions, building codes, and utility practices allows us to provide faster response times, more accurate assessments, and smoother permit coordination. This local insight streamlines the inspection process and ensures our solutions are perfectly suited to the specific needs of businesses in this area.

What Certifications and Experience Do Our Commercial Electricians Possess?

The B-Line Electric team holds licenses from the Ontario Electrical Safety Authority and certifications in NFPA 70E, backed by years of experience in both residential and commercial electrical work. This extensive expertise guarantees that our inspections meet and exceed industry standards.

How Does B-Line Electric Ensure Safety and Quality in Every Inspection?

Every inspection we conduct follows a standardized checklist, utilizes calibrated testing equipment, and adheres to documented procedures aligned with NEC, NFPA, and provincial codes. Our digital reporting and photographic evidence provide transparent audit trails and clear guidance for any necessary corrective actions.

How Are Electrical Safety Solutions Customized for Different Business Needs?

B-Line Electric tailors inspection scopes based on your facility's size, industry-specific risk factors, and operational priorities. Whether you run a retail shop, a warehouse, or a manufacturing plant, our solutions are designed to deliver maximum safety and compliance value for your unique situation.

What Are Common Questions About Commercial Electrical Safety Inspections?

Businesses often have questions about why inspections are important, how often they should be done, what they cover, the costs involved, the return on investment, and how to prepare. Understanding these aspects helps decision-makers plan effectively and work with qualified inspectors:

Inspection Importance: Inspections are vital for protecting people, assets, and maintaining compliance.

Scheduling Intervals: Annual or semi-annual inspections offer a good balance for risk management and code adherence.

Scope of Work: Typically includes panels, wiring, grounding, protective devices, and hazard assessments.

Cost Considerations: This investment leads to reduced downtime, lower insurance premiums, and extended equipment life.

ROI and Benefits: Long-term savings are achieved through improved energy efficiency and fewer repair expenses.

Preparation Steps: Gather equipment documentation, ensure safe access to all areas, and coordinate with your maintenance teams.

Understanding these key areas simplifies the inspection process and builds confidence in your electrical safety decisions.

Protecting your business from electrical hazards requires proactive inspections, expert analysis, and tailored corrective actions. B-Line Electric's comprehensive services provide code-compliant, energy-efficient solutions that enhance uptime and ensure personnel safety. Schedule your commercial electrical safety inspection today to secure uninterrupted operations, gain peace of mind regarding regulations, and achieve cost savings for years to come.